Producten

- Vaste stoffen controleapparatuur

- Triple Deck Shale Shaker

- Lineaire beweging Shale Shaker

- Vacuüm Degasser

- Modder schonere

- Desander

- Desilter

- Decanteren Centrifuge

- Sludge Vacuum Pump

- Verticale snijden droger

- Drogen Shale Shaker

- Jet modder Mixer

- Modder Agitator

- Centrifugaalpomp

- Schuintrekken pomp

- Onderdompelbare drijfmest pomp

- Modder Gun

- Modder Gas scheidingsteken

- Brand ontsteking apparaat

- Schroef pomp

- Hydratatie Tank

- Modder Tank

- Elevated Oil Tank

- Diesel Tank/Oil Tank

- Motor Control Center kamer

- Schroef transportband

- Offshore Mud Skip Container

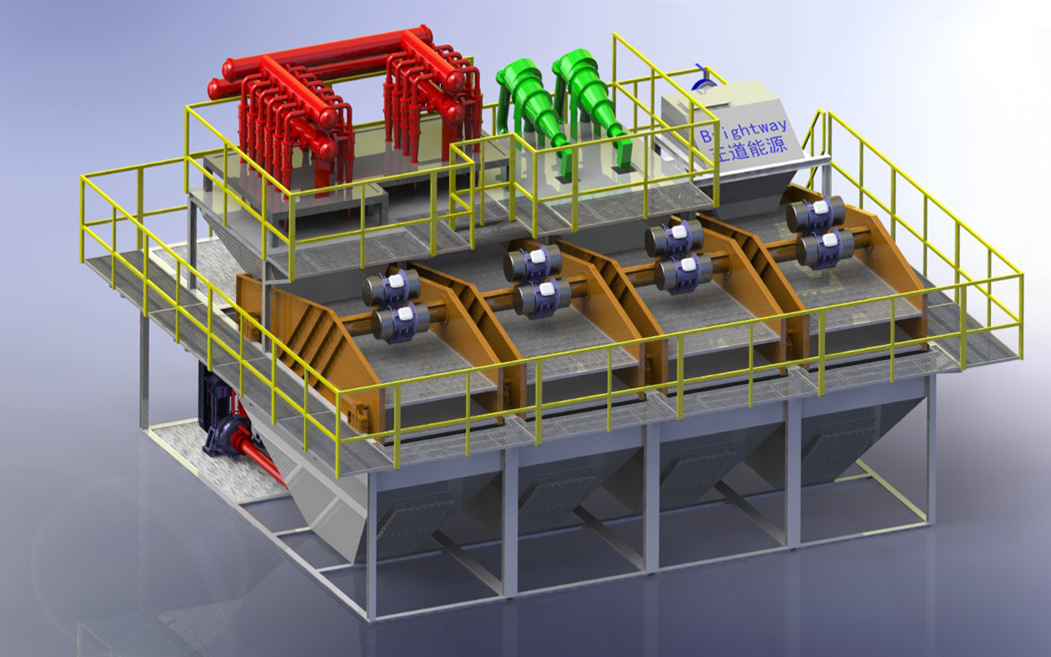

- Vaste stoffen controlesysteem

- Reserveonderdelen

- Drilling Rig

Contact

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Gevallen

-

3000hp Drilling Rig Circulation System for 9000m U...

3000hp Drilling Rig Circulation System for 9000m Ultra Deep Drilling Proj...

-

2000hp Drilling Rig Mud Tank System for Saudi Arab...

2000hp Drilling Rig Mud Tank System for Saudi Arabia As earl...

Technologie nieuws

Separation Plants for Traffic Tunnelling

2022-05-30

The slurry separation plant is optimally matched to the requirements of the traffic tunneling process and separates the mud from solid particles of various sizes (gravel, gravel and sand). Using the most advanced screening technology and hydraulic vacuum cyclone separator with powerful G force, the solid is separated from the mud. Efficient separation procedures have the following essential characteristics.

The mud is thoroughly separated and dewatered until a very low residual moisture content is achieved; bentonite and other additives are added according to the geological conditions. The less residual moisture, the lighter the muck to be separated and the lower the cost of spoil. In addition, when excavating in sandy and cohesive soils, if fine particles remain in the suspension, the ability of the mud to absorb solid slag particles will be reduced, which will affect the traffic tunneling speed. In this case, additional filter presses and centrifuges should be used to avoid thickening of the muddy water.

One of the advantages of slurry shield equipment is its wide application in heterogeneous geological conditions. If soil and rock conditions change, the screening pads in the slurry separation plant must be replaced. Using the quick screen replacement technology developed by Brightway, the screen replacement can be completed in the gap when the tunnel excavator stops driving for pipe ring installation without any additional tools. Cost-effectiveness is improved due to the use of durable and easy-to-maintain polyurethane screen panels or steel screens, and the entire mud-water separation plant achieves high operating efficiency.

One of the standard configurations of Brightway Slurry separation plant is the modular container design, which can be expanded, reduced or moved quickly and easily. Based on this feature, the slurry separation plant can be flexibly modified according to specific applications, and the assembly and dismantling speed is fast and the cost is low. The internal settings of the slurry separation plant also adopt a modular design making maintenance, equipment repair and parts replacement fairly easy.

Vorige :Types of Decanter Centrifuges