Oily Sludge Treatment System

Brightway is a company that designs and produces Oily Sludge Treatment System and Oily Sludge Disposal Equipment, as well as Oily Sludge Separator in oil fields. Those technologies and equipment can be widely used in oily sludge treatment and recovery in oil drilling, petrochemical and other fields.

Oil-sludge Treatment Equipment ( Oily Sludge Treatment System)

What is the Oily Sludge?

Oil Sludge is known as oily sludge, oil-containing silt,polluted oil and silt etc. During the drilling process, the oil-containing silt,which brought from replacing the well-drilling and extracting the drive pipe, will be left around the well site. The oil-containing silt that is covered with various sands and sundries, etc., will be piled up more and more before the site is cleaned up or the oily sludge is temporarily piled up for a period of time. The oily sludge comes from the deep drilling strata, and contains a large number of benzene series, phenols, anthracene, pyrene and other odorous toxic substances. It will not only damage the soil or pollute the environment, but also cause the waste of resources if not treated well.

The Generation of Oily Sludge

Oily sludge is a kind of oil-containing solid waste generated in the process of oil exploitation, transportation, refining and oily sewage treatment. It is one of the main pollution sources in the production process by the oil field enterprises. There are various kinds of oily sludge,and their natures are complex. Oily sludge generated in the process of crude oil exploitation mainly comes from the surface treatment system — the oily sludge generated in the process of oil extraction sewage treatment, and from the composition of alum floc, pipeline corrosion products, scale, bacteria (corpse) in sewage purification process. Besides, for petrochemical enterprises,a small amount of mechanical impurities, sand grains, soil, heavy metal salts, paraffin, asphaltenes and other heavy oil components are deposited at the bottom of the oil tank, forming tank bottom oily sludge.

The Harm of Oily Sludge

On the one hand, oily sludge contains a large number of benzene, phenols, anthracene, pyrene and other odorous toxic substances, and if not treated timely, will seriously pollute the soil and the environment; on the other hand, Failing to collect oily sludge timely will cause the waste of resources:generally, the oil content of sludge is 10 ~ 50%, and the water content is 10 ~ 60%. The crude oil is rich in sludge,and if the crude oil is separated and extracted from the sludge, the water content of the crude oil is less than 4%, which conforms to the crude oil recovery standard and can be recycled by the crude oil recovery plant or the refinery to realize economic value.

Brightway Oily Sludge Treatment Process

At present, there are many technologies for processing oily sludge in China, among which the thermal analysis and the thermal desorption treatment are used widely. The oily sludge thermal analysis treatment scheme adopts the closed high temperature liquefaction gasification method, which causes bad effects, such as high energy consumption, difficulty in collecting crude oil, low treatment efficiency (about 5 tons/hour), and relatively high treatment cost. The sludge thermal desorption treatment scheme, with low energy consumption, low input, recovery of crude oil, high treatment efficiency (about 20 tons/hour), is quite economical, efficient and easy to put into production, becoming a widely used oily sludge treatment scheme.

Based on the characteristics of oily sludge, the technical advantages of solid-liquid separation integration scheme, and years of experience in researching and applicating of solid-liquid separation equipment system in oil field, Brightway developed the economical and efficient solution of Oily Sludge Treatment.

Step 1: Through the sorting equipment, the stones, weeds, roots and other debris in the oily sludge can be sorted.

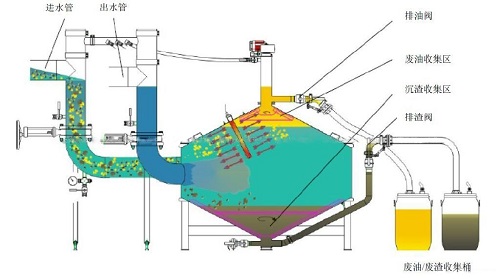

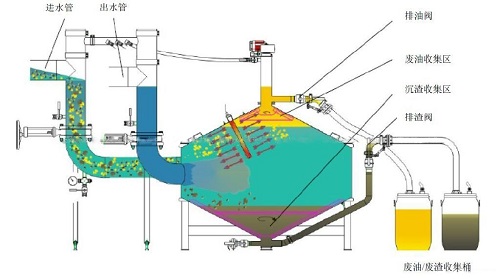

Step 2: Using the heating tank equipment, stirring equipment, and dosing equipment, and making use of the different gravity of oil and water can make water fully stratified: Oil, which account for the smallest proportion, is on the top layer, Water is in the middle layer, and sand is at the bottom.

Step 3: Using three phase separation equipment, oil and water separation equipment and mud and water separation equipment can realize the three phase separation: water oil and mud; and the recovery of crude oil. The muddy water enters the mud and water separation equipment , where it can be recycled to the heating tank or further treated by the water treatment equipment.

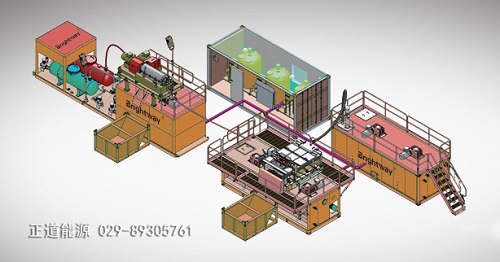

Brightway Oily Sludge Treatment System

According to the Oily Sludge Treatment Solution, Brightway has designed a complete set of integrated oily sludge treatment system,which has the characteristics of flexible equipment selection, flexible configuration, low input and high output. Brightway’s oily sludge treatment system is composed of sludge pretreatment equipment, sludge screening equipment, dosing system, oil-water separation equipment, mud-water separation equipment and other equipment.

Oily Sludge Treatment System Cases

Bightway has designed and produced integrated solutions for oilfield sludge and oil-based mud treatment in provinces of Liaoning, Sichuan, Inner Mongolia, Xinjiang, Gansu and Shandong etc. As a professional oily sludge treatment equipment manufacturer, Brightway can provide customers for designing integration solutions, and providing special oily sludge treatment equipment and systems according to the specific situation of the oil fields, to realize the economical, large scale, and environment-protective recycling of oilfield oil sand.

Contact Us

Email: brightway@bwwell.com

Tel: +86-29-89305761

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769