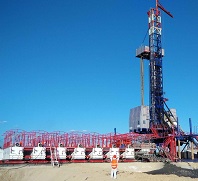

Drilling Mud Mixing Equipment

2022-01-29

In field of oil drilling mud treatment, drilling mud mixing equipment includes

mud mixing agitator, mud mixing hooper, mud mixing tank. These drilling mud mixing equipment are assembled into a mud mixing system. Mud mixing equipment is used to add different chemical additives to dilling fliuds and keep mud properties.

Various chemicals or additives are also used in different situations. The drilling fluid continuous phase is usually water (freshwater or brine) called water–base fluids. When the continuous phase is oil (emulsion of water in oil) it is called oil–base fluid. Water base fluids are normally made at the rig site. oil base mud and synthetic fluids are normally manufactured in a drilling fluid plant. Special treatment and mixing equipment exists for this purpose. Mud mixing agitators, mud mixing hoppers, and other mud mixing equipment are used for these purposes.

1. Mud mixing agitator

Mud mixing agitator is located on the mud mixing tank, It is used to mixing mud after processing by solid control equipment, such as shale shaker, desander desilter, decanter centrifuge. The aim of agitator is homogenize the fluid in the tank. . It help to keep the various suspended material homogeneously distributed in the tank. By forcing toroidal and whirl motions of the fluid in the tank. Mud mixing agitators includes horizontal and vertical types and the porwer of 7.5kw (10hp) 15kw (20hp) 22kw (30hp).

Mud mixing hooper includes one sand pump, one venturi mud mixing hopper and one jet mud mixing hopper and pump that are installed in a base with pipe valves. It is special equipment to prepare and increase the drilling fluids weight by adding and mixing bentonite, change the fluid density, change the mud density, viscosity, and dehydration. The effect is more prominent matching with Shear Pump. Mud mixing hooper is a unit used together with the solids control system for petroleum drilling and horizontal directional drilling.

3. Mud Mixing Tank

There are options for 200GPM, 500GPM, 800GPM and 1000GPM mud mixing tank. Different mud flow will match different size of mud mixing pump and mud mixing hopper with suitable size of pipeline. The mud mixing tank normally lay at end of mud tanks stem and close the mud chemical storage for mixing convenient. The mixing pump suction and discharge line will connect with all clean mud storage tank with mud pump suction line as well. The connections between tanks are normally union for fast moving and connecting. The mud mixing tank will keep extra valves at each connection for convenient operation.

Vorige :Brightway Wishes the People of the Country a Happy Spring Festival and an Auspicious Year of Tiger

Volgende :Mud Recycling Unit for Directional Drilling

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769